|

D9 Automated circular sawmill (with two rectangular saw blades) cuts high quality sawn timber - furniture, pallet blanks or radial and tangential timber. By gradually sawing individual slabs / prisms, it is possible to process the entire trunk into finished products. Operator is sitting in an air-conditioned sawmill, while the automated system separates the waste and sorts the timber according to its length and dimensions, with a high yield of high-quality and accurate centre timber.

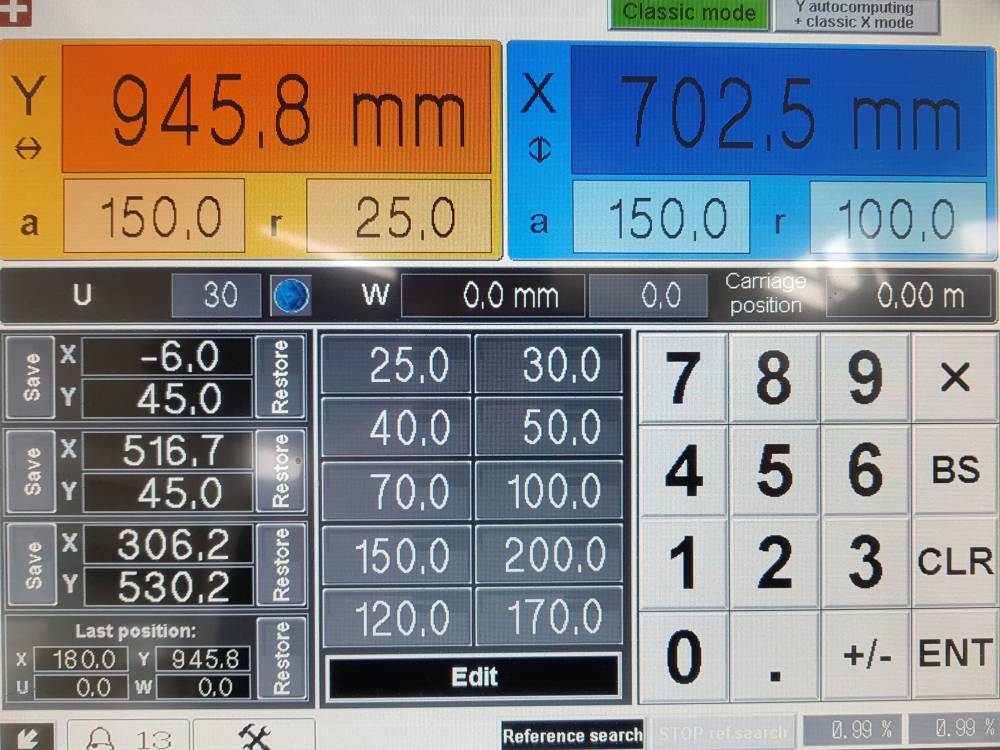

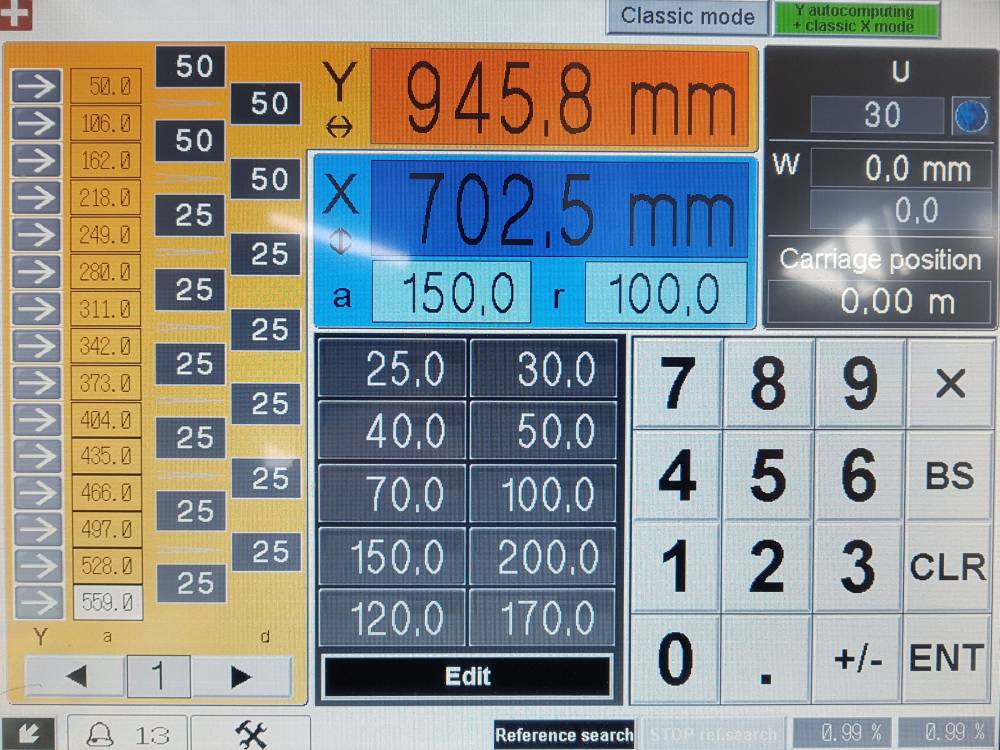

Operator's workplace

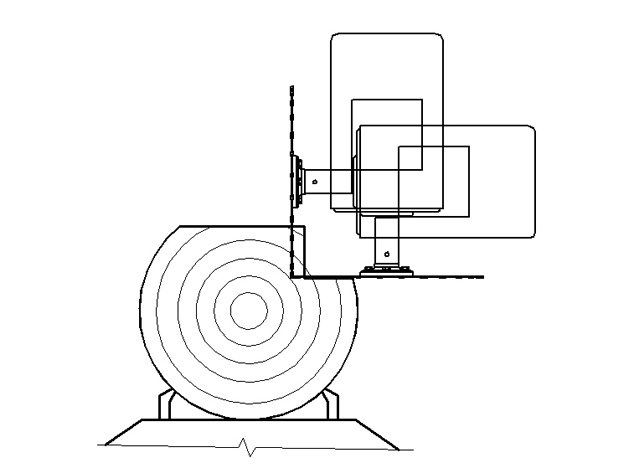

The principle of rectangular sawing

As well as other circular sawmills from StrojCAD, the D9 saws large-diameter logs with a small saw blade. The small thickness of the saw blade guarantees low waste and high yield, because the high precision of the lumber allows for a smaller choice for further processing. Optical transducers are provided on each clamping module to measure the diameter of the log, which is used to automatically adjust the first cut and compensate the conicity of the strain every time it is rotated. Measuring the length of the log and the position of the carriage on the track allows you to reliably set the start and end of the cut. The carriage is then moved automatically between these two positions with the aid of other automation functions, without the need for operator intervention in the sawing process.

Compensating the conicity of the log by slanting the towers

Setting the first cut with laser sensors

The stationary Circular Saw Headrig is formed by two mutually perpendicular saw blades.

Rectangular cutting mechanism

Stationary D9 Circular Saw Headrig

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|