Spoločnosť StrojCAD, s. r. o. patrí v súčasnosti k významným výrobcom drevoobrábacích strojov na Slovensku.

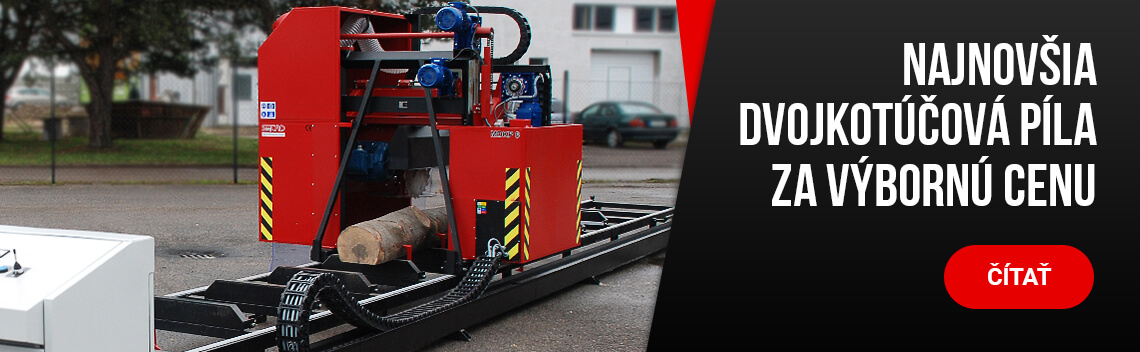

Profesionálne drevoobrábacie stroje – automatizované kotúčové píly vyvíjame a vyrábame už od roku 1992. Významná časť produkcie je určená pre zahraničných odberateľov. V súčasnosti náš výrobný sortiment tvorí široká škála piliarskych strojov pre drevospracujúci priemysel, postavených na báze kotúčových technológií. Naše uhlové kotúčové píly na porez guľatiny využívajú jedinečné originálne riešenia, ktoré sa vyznačujú robustnou konštrukciou, jednoduchou obsluhou, vysokou kvalitou a spoľahlivosťou.

Vďaka tomu sme stále o krok pred konkurenciou a na trh prinášame len kvalitné a inovatívne piliarske technológie.