|

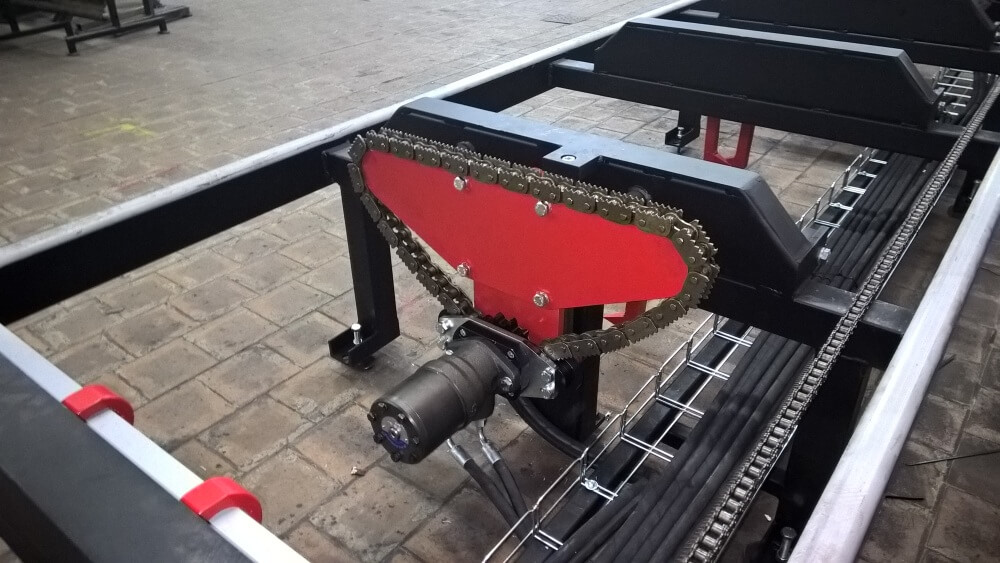

The UH500 Circular swing-blade sawmill is a machine for the production of finished timber. By using the proven turning sawing mechanism for single-pass, back-and-forth production, it produces plastered boards, blanks, laths, prisms in planed timber quality and in high precision. The swing-blade cutting mechanism, developed by StrojCAD for circular swing-blade sawmills, is tilted 90 degrees. This system allows cutting in both directions.

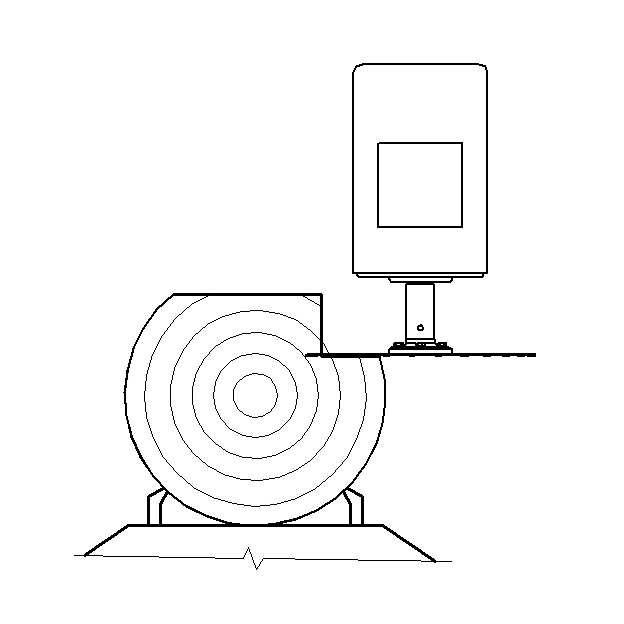

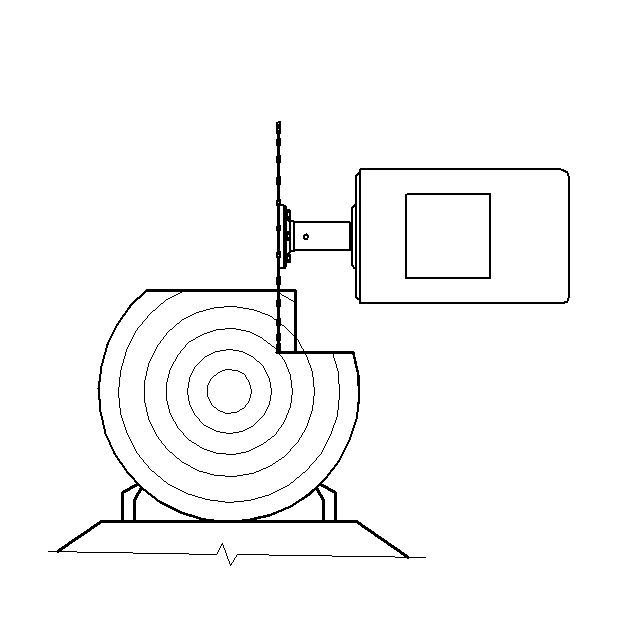

Horizontal cut

Vertical cut

As standard, the UH500 is equipped with automatic override and width adjustment and continuously adjustable frequency invertor feed. Low installed power, low cost, high work productivity, and solid cut performance ensure that rapid return on investment in the machine is achieved. No additional machines are required because the UH500 Circular swing-blade sawmill produces final products - the best quality sawn timber. You can also cut soft and hard wood with high surface quality up to 800 mm in diameter when using a saw blade.

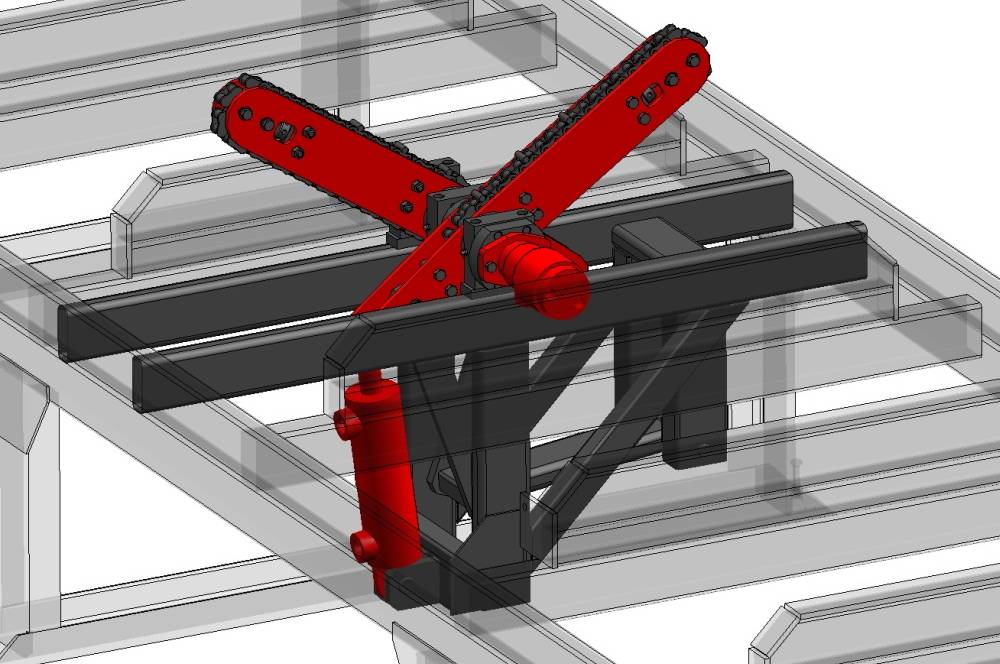

Cast iron 15 kW electric motor

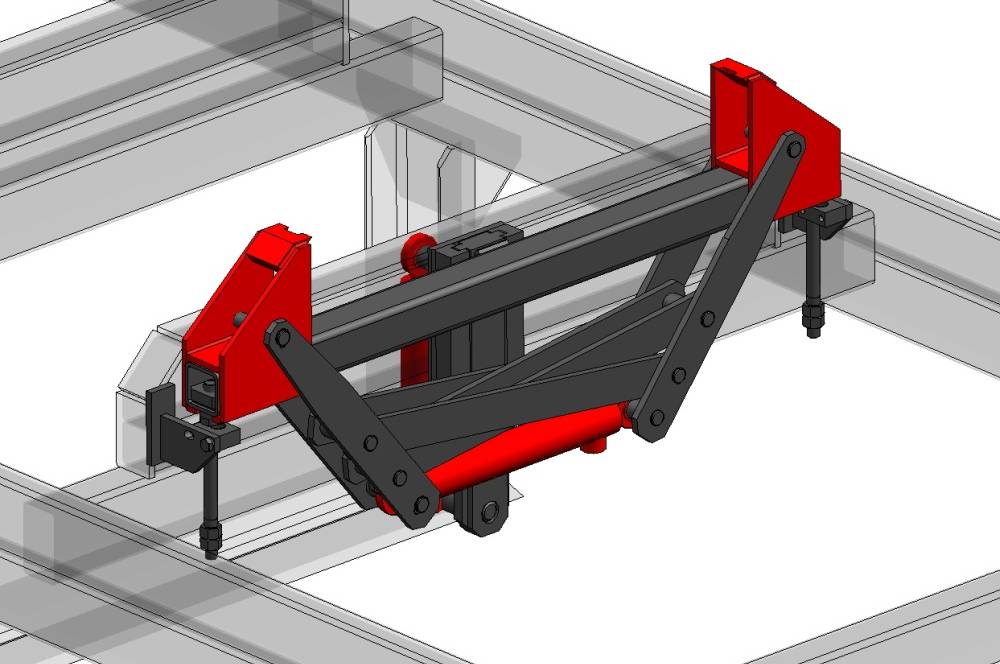

Clamping frame for radial sawing

For cutting radial sawn timber, the saw can be equipped with a special clamping frame to maximize the timber yield of the logs with greater convergence. The UH500 Circular swing-blade sawmill can be supplied with a seat and control panel on a saw head, or a stationary control panel in front of the machine frame. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

UH 500 Circular Swing-Blade Sawmill

- Best-selling circular swing-blade sawmill

- Small machine with great cuts

- Lowest operating costs per m³ of processed logs

- Easy operation and maintenance, reliable operation

- Production of precision sawn timber directly from logs with just one machine

- Max. Log diameter 80 cm, max. Log length 12 m, max. Prism 20 x 20 cm

- Reliable cast iron motors 15 kW or 18.5 kW

- One-person operation

MACHINE CONTROL

The automatic dimensioning allows you to quickly and accurately adjust the cut range.

Saw timber adjustments are made by moving the saw head in two axes using the control unit directly by selecting the display or recalling and value from the memory.

Control panel

Hydraulic control panel

The UH500 Circular sawmill standard is equipped with a fully automated cutting cycle:

- Tilting the saw blade to a horizontal position

- Cut back

- Slowing and stopping the saw carriage at the end of the runway

- Adjusting the cutting dimension

- Forward horizontal cut

- Tilting the saw blade to the vertical position

- Slowing and stopping the saw head carriage

- Selecting the next pre-set size as desired

Operator activity is maximally free of routine operations. The operator regulates the cutting speed and selects the cut dimensions depending on the quality of the wood, thus maximizing the efficiency of the wood mass.

HYDRAULIC LOG HANDLING

The sawmill is equipped with clamping clamps as standard. Also available as optional accessories are trunk lifters to the trimming of the residual cut-outs.

Log loader for saw frame

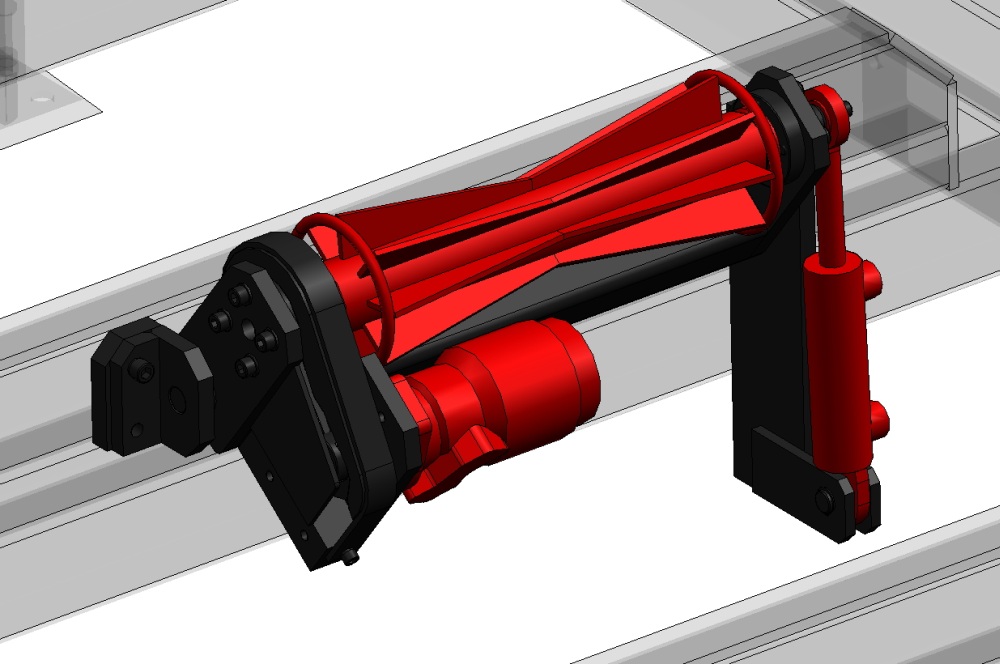

Log turner with convergence function

Clamp with lifting cylinder

Slide roller for longitudinal feed of the log

However, hydraulic handling of logs (loading, clamping, turning, aligning and centring) will also help to increase yield and change performance in addition to ease of handling.

The universal "L" turner does not only serve to rotate the logs, but also to fit them appropriately on the clamping frame before clamping them. The turner allows you to lift the thinner end of the trunk or move it horizontally to position the trunk in its optimum position and compensate for its convergence, which has a major impact on timber quality and cut yield.

STROJCAD RECOMMENDS