|

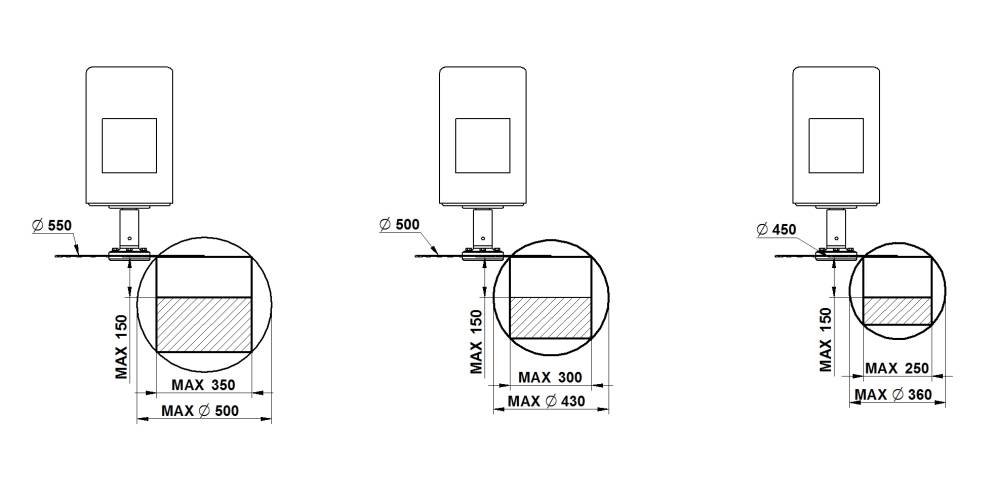

The KP58S Circular sawmill, from StrojCAD, is designed primarily as a sawing saw for thin wood cutting with a pair of horizontal saw blades (450, 500 or 550 mm diameter) but also for producing untrimmed and trimmed sawn timber - boards, planks, prisms, for finished blanks - pallet, parquet, furniture. The KP58 is capable of processing logs up to 500 mm in diameter and up to 12 m in length. The clean cut is max. 350 mm. We supply KP58 circular saws in stationary versions with or without hydraulic equipment. A pair of saw blades provides solid performance with high stability, high timber accuracy and superior surface quality.

Horizontal saw blades

Cast iron 15 kW electric motors

Low operating costs, ease of use and low maintenance guarantee high productivity and cost-effective operation with a rapid return on investment in the machine. The sawmill does not require a special base for its installation, just a flat surface made of concrete or panels. Basic versions of the KP58S are supplied with main electric motors of 2 x 15 kW. To increase the power of the cut, the sawmill can also be ordered with electric motors 2 x 18.5 kW.

Cutting parameters for different saw blade diameters

Since the saw blades cut into the centre of the log while sawing, the debris is thrown out, with minimal wear of the circular saw blades compared to other tools (band blade, frame saw). This results in a considerably longer lifetime of the saw blades and a much lower operating cost. Thus, a smaller supply of saw blades is sufficient for operation. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

KP58S HORIZONTAL CIRCULAR SAWMILL

- Replacement for a band sawmill

- Carefree operation, no problems with sawing tools

- A simple saw blade sharpener is sufficient

- Suitable for production of untrimmed and trimmed planks, deals, blanks, prisms or final laths

- Easy motor changeover when changing saw blades (450, 500 and 550 mm)

- Max. Log diameter 50 cm, max. Log length 12 m, max. cutting width 35 cm, max prism height 15 cm

- Reliable cast iron motors 15 kW

MACHINE CONTROL

The movement of the saw head into the cut is controlled by the frequency inverter. To increase operator comfort and change performance, we normally supply a sawmill with a computerized cut height adjustment.

Adjusting the timber dimensions is via the control unit directly on the display using the control unit.

Control panel

Hydraulic control panel

After cutting, and before moving the saw head to the beginning of the next cut, the saw blades are raised by a pre-set value to prevent them from rubbing backwards.

When the next thickness is selected, it is precisely adjusted without having to adjust the position of the saw blades to the previous cutting height.

HYDRAULIC LOG HANDLING

KP58S Circular sawmills without hydraulic log handling are supplied with clip-on clamps and folding supporting steady, necessary for skidding up the trunk and cutting the prism timber.

Log loader for sawmill frame

"V" log turner with convergence function

Vertical Lift Clamp

Slide roller for longitudinal feed of the log

For hydraulic versions, standard hydraulic equipment consists of:

- Loader – used to load logs on a workbench that is 750 mm above the ground for hydraulic versions,

- Tilting hydraulic supporting steady – used to align log after being loaded onto a workbench and centre them, while providing double cuts also ensure perpendicular alignment to the working table,

- Log turner – single or double-arm, for convenient log handling, for turning when sawing, and suitable for bench positioning,

- Clamps – a unique clamping system that perfectly fixes wood. It precludes its springing when sawing, and in that the chucks are also adjustable in height, they allow horizontal alignment of the log along its entire length while tightening the log to the machine bed,

- Scroll roller – to move logs along the frame length.

Single-arm log turner

Folding supporting steady

STROJCAD RECOMMENDS