|

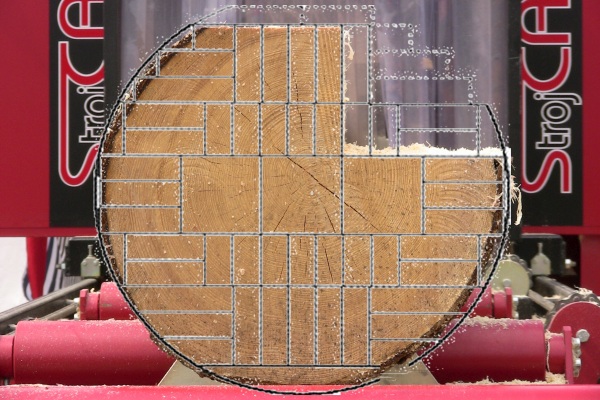

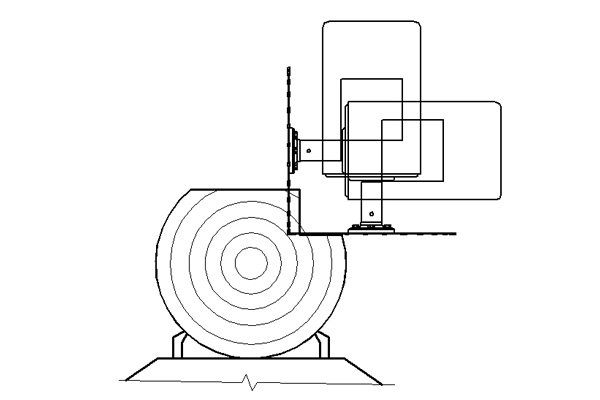

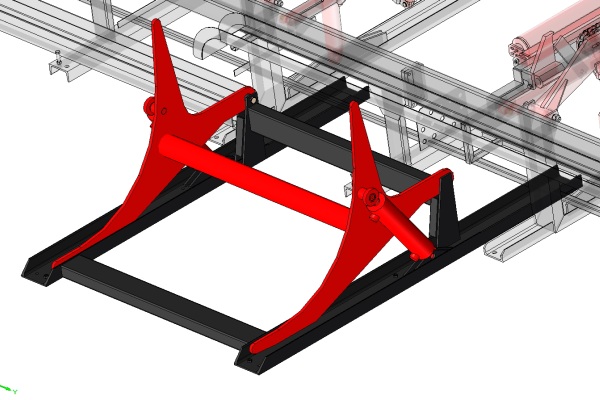

The MDKP6 Circular sawmill uses the proven design of a rectangular cutting mechanism, developed by StrojCAD for a larger circular saw DKP6, with two mutually perpendicular saw blades that allow it to cut "sharply" in both directions in a suitable timber range so as to significantly increase the cut capacity saw. The firm and precise cutting mechanism allows you to cut a maximum prism of 20 x 20 cm in both directions.

Optimum yield of quality timber

The principle of rectangular sawing

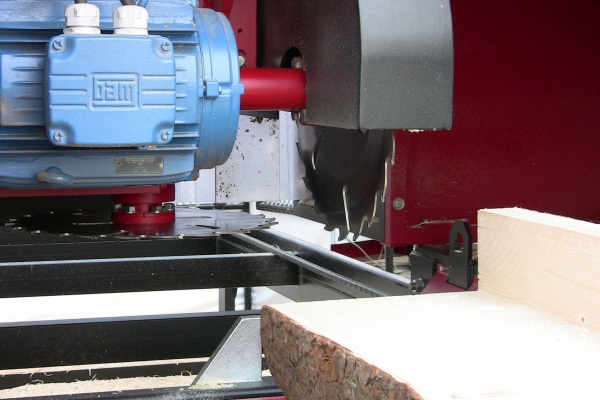

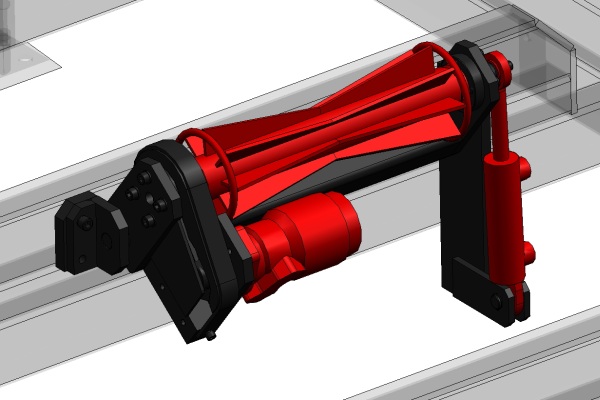

The MDKP6 Circular sawmill can cut logs up to 70 cm in diameter and up to 12 m in length with a clamping frame length of only 17 m. However, even longer trunks can be cut on a custom-made elongate chassis. The use of saw blades with diameters of 400 to 550 mm gives high variability in the timber range. Thus, the customer is also able to use small saw blades with minimal cut thickness to cut small sizes, blanks, radial sawn timber or for cutting precious woods, reducing waste and increasing yield. However, even construction timber is a toy for the MDKP6 Circular Saw. With the use of 550 mm saw blades, the sawmill can cut all commonly needed prisms, rafters, grouts, etc. for building. It is possible to process the entire log into finished products by gradual sawing of individual boards/prisms. Excellent surface quality and high timber accuracy are a matter of course with the MDKP6 Circular Sawmill. Two robust 15 or 18.5 kW cast-iron motors, a firm cutting mechanism design and a complete saw head, precise dimensioning and a stable clamping frame guarantee reliable and successful use even in continuous operations.

Rectangular cutting mechanism

Cast iron 18,5 kW electric motor

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

MDKP6 Circular Sawmill

- The most cost-effective double-saw blade sawmill

- Cutting prisms and boards with two saw blades in both directions

- Production of precision sawn timber directly from logs with just one machine

- Horizontal and vertical alignment of the convergence of the logs - high yield of quality timber

- Max. Log diameter 70 cm, max. Log length 12 m, max. Prism 20 x 20 cm

- Very quick adjustment of saw mechanism to cut size

- Stationary control panel and hydraulic log handling increase operator comfort

- Reliable 2 x 15 kW or 2 x 18.5 kW cast iron motors

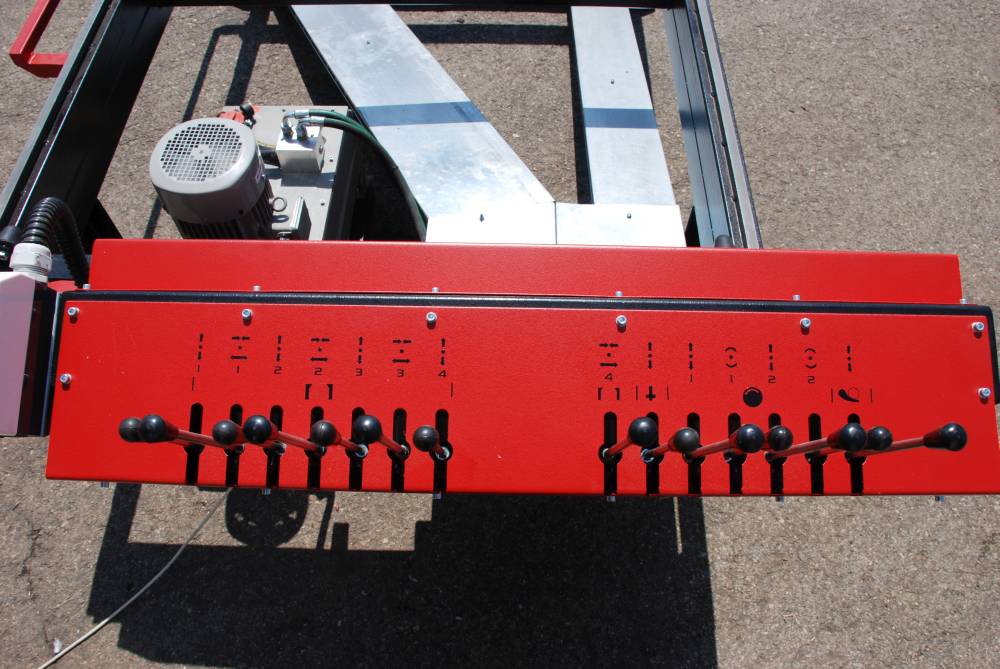

MACHINE CONTROL

Proven, very fast, comfortable and user-friendly saw control gives the operator the ability to maximize wood mass in the best quality timber. High performance can already be achieved with standard saw versions.

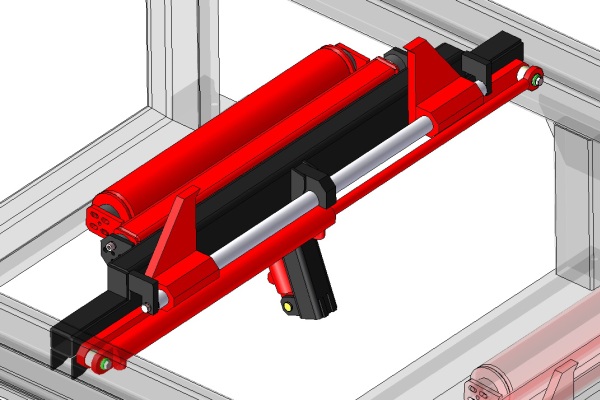

The control panel and the electrical switchboard outside the saw head make it possible to increase the cutting speed and the dynamics of the saw blade even more, and also to increase operator comfort and ease of service.

Control panel with electrical switchboard

Hydraulic control panel

Automated cutting cycle with automatic dimensioning is included in the basic equipment of the machine. Adjusting the timber dimensions is done by shifting the saw head independently in two axes using the control unit directly by dialling from the keyboard or by recalling a value from the memory. The vertical and horizontal adjustment of the cutting mechanism is controlled by a powerful frequency converter, which significantly accelerates the return of the saw blades to the starting position.

HYDRAULIC LOG HANDLING

Log loader for saw frame

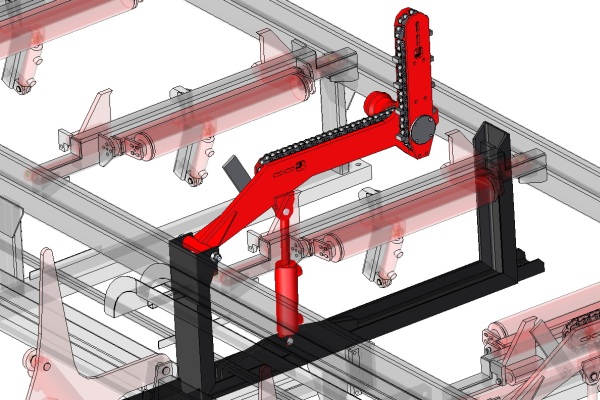

Log turner with convergence function

Clamp with lifting cylinder

Slide roller for longitudinal feed of the log

However, hydraulic handling of logs (loading, clamping, turning, aligning and centring) will also help to increase yield and change performance in addition to ease of handling.

The universal "L" turner does not only serve to rotate the logs, but also to fit them appropriately on the clamping frame before clamping them. The turner allows you to lift the thinner end of the trunk or move it horizontally to position the trunk in its optimum position and compensate for its convergence, which has a major impact on timber quality and cut yield.

STROJCAD RECOMMENDS