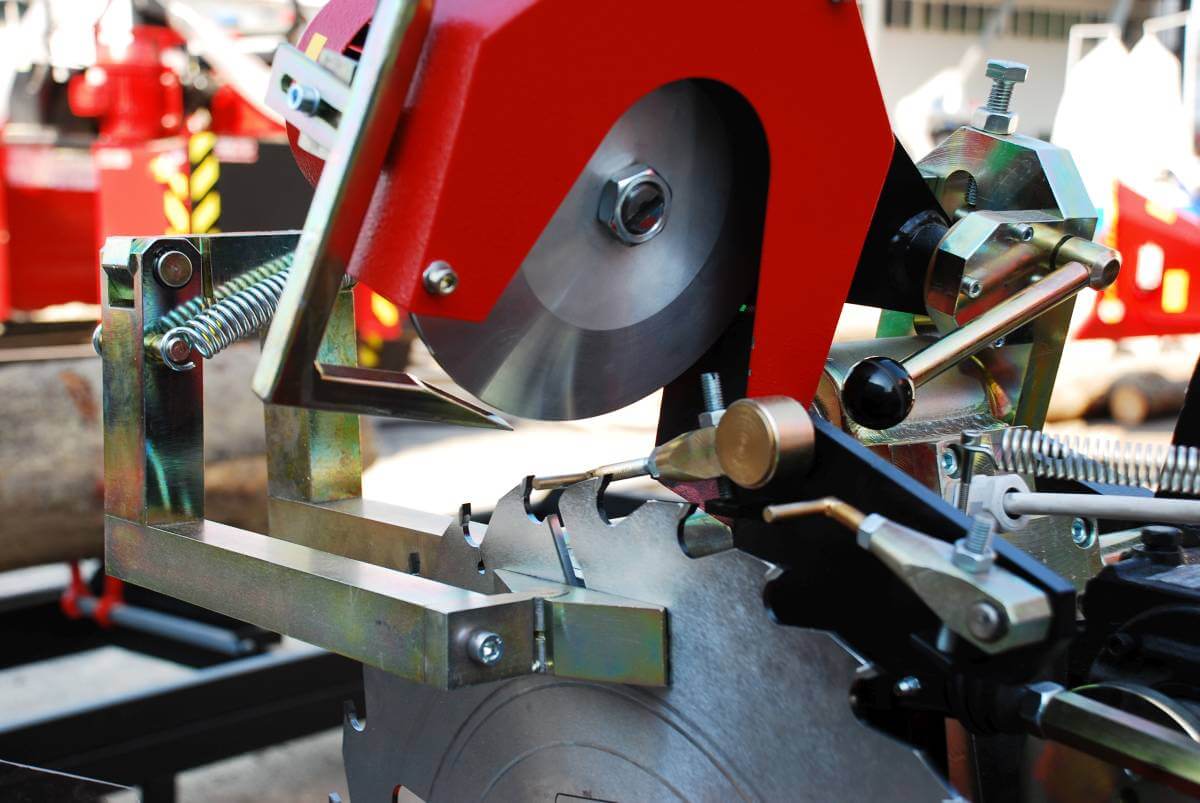

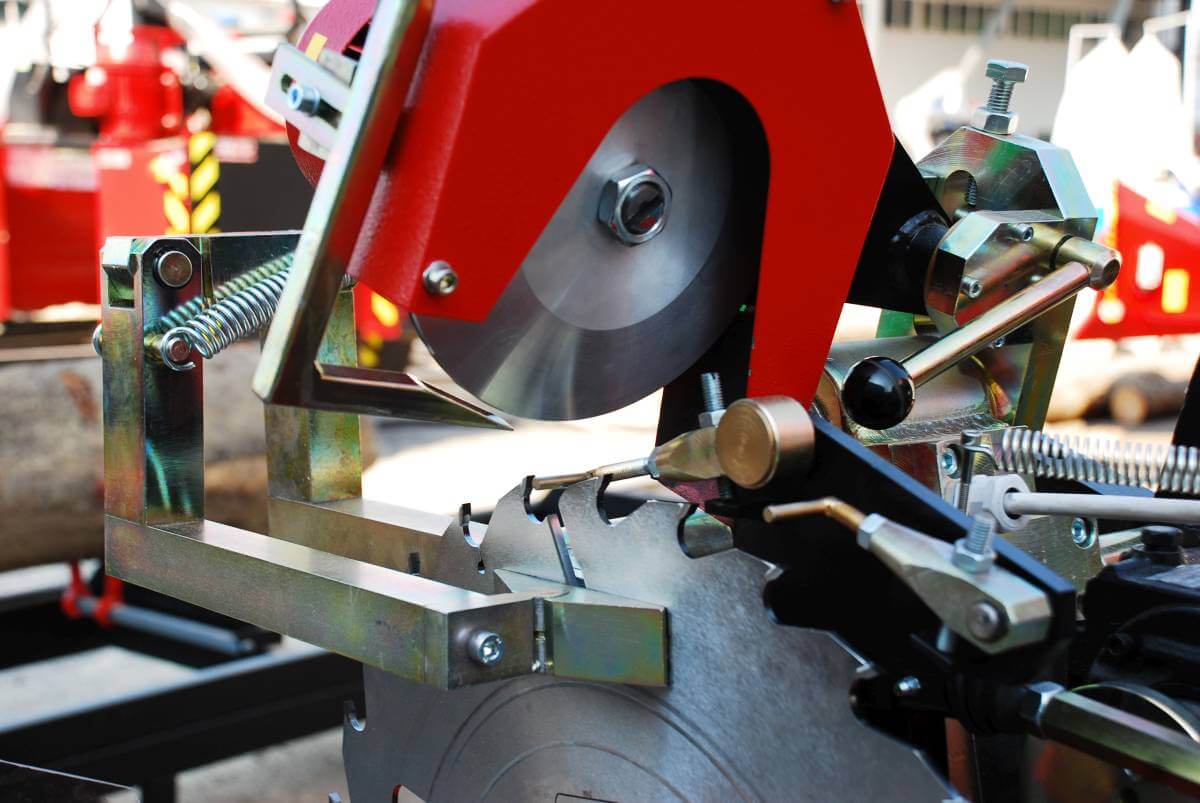

BU 800K and BU 1200K – semi-automatic sharpener for circular sawmills for dry cuttingSemi-automatic sharpener without cooling at the point of sharpening is intended for sharpening saw blades for longitudinal cutting with straight faces and backs. The sharpener is intended for sawmill operations, as a supplementary machine for sharpening saw blades of all types of circular sawmills of the company StrojCAD, but also for sawmills of the type Laimet or Kara (variant up to max. Diameter of saw blade 1200 mm). Feeding the saw blade, with the feed speed control to the point of focus, is a feeder, guided along a circular path, copying the tooth path to the point of focus. The sharpener is designed for a wide range of saw blade diameters and tooth pitch, which significantly increases its utilization. The sharpener is equipped with infinitely variable feed control via a frequency inverter. It is also possible to complete the grinder with frame or band saw blades.

BUH 800K a BUHS 800K – semi-automatic sharpener for circular sawmills with coolingSemi-automatic coolant sharpener (BUH 800K and BUH 1200K) is built on the basis of the universal sharpener BU, with their typical characteristics. However, the lower part of the sharpener is designed to function as a coolant collection container. It also includes a pump and filter device, as well as electric cabinet, specially adapted and fitted with components for very low voltage, thus meeting the safety requirements for wet operation. When using a diamond sharpening wheel and with a cam for recessing sharpening, it is possible to sharp the saw blades with SK (TK) slices on this sharpening machine (BUHS 800K). The sharpener is equipped with infinitely variable feed control via a frequency inverter. It is also possible to complete the grinder with frame or band saw blades.

BU 2001 – hand sharpener for circular sawmillsBU 2001 is a hand sharpener designed for precise and fast sharpening of saw blades for longitudinal cuts (even with sintered carbide slices ces) of 150 to 700 mm diameter. The sharpener has a firm construction with the possibility to be attached to a workbench. A special delivery mechanism allows very precise delivery of each tooth to the point of focus. It is also possible to sharpen the face of the saw blades on the sharpener. It is also possible to adjust the angle of the forehead and back. The sharpener is designed for everyday sharpening of saw blades in sawmills.

|

||||||||||||||||||||||||||||||||||||

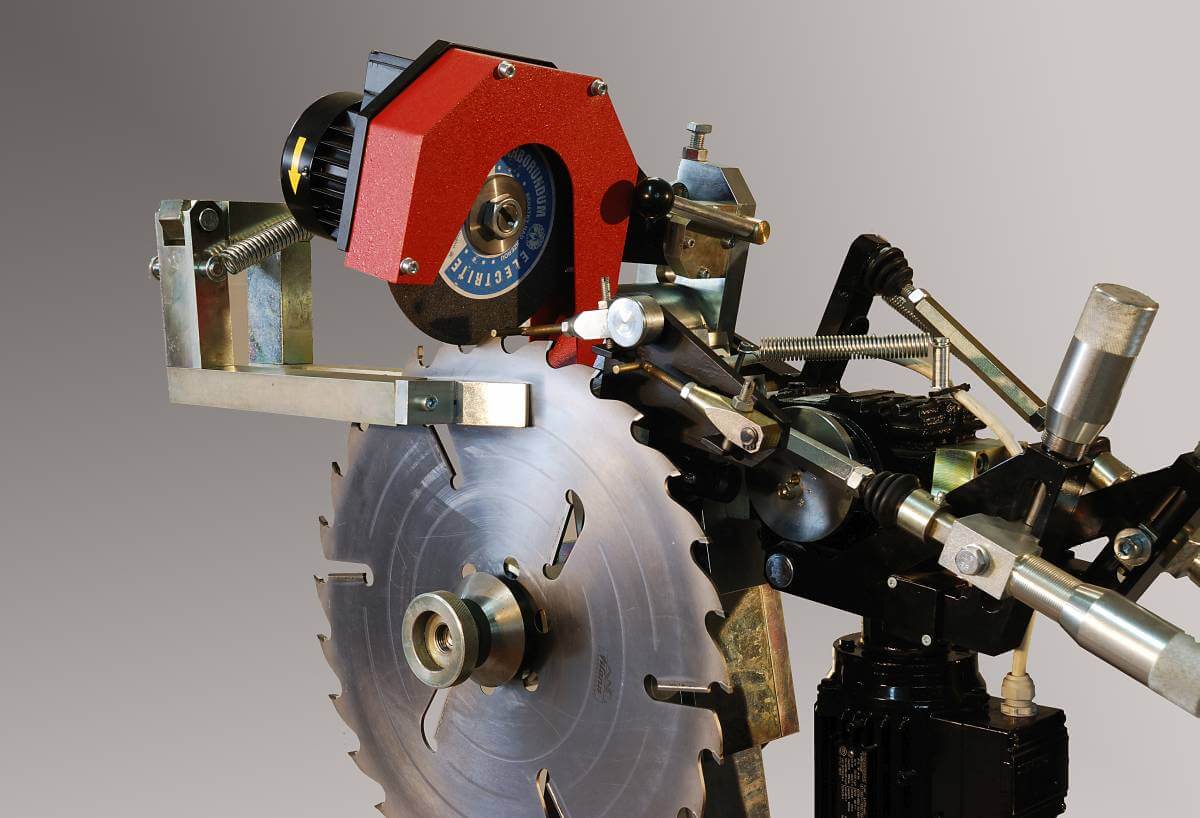

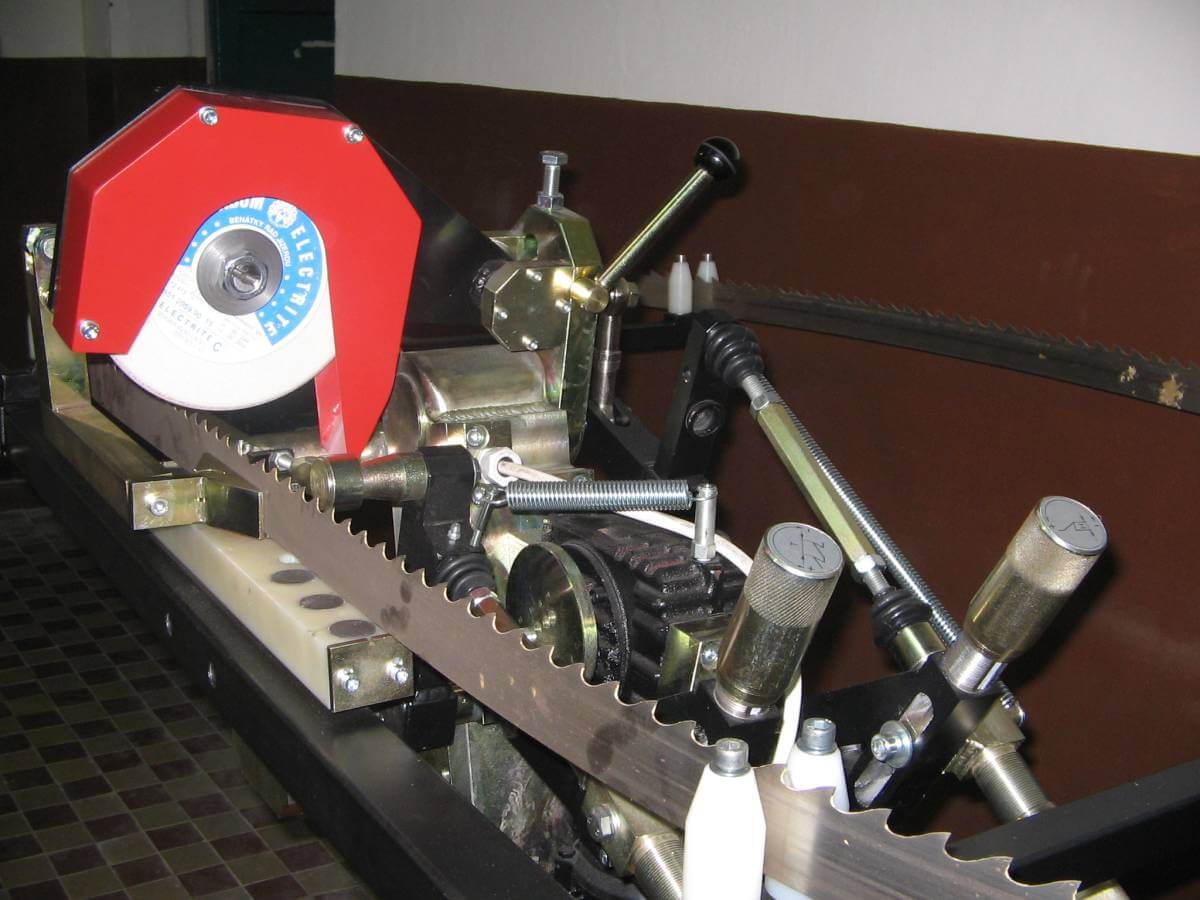

BU 800P – semi-automatic sharpener for belt sawmillThe semi-automatic universal sharpener of the BU series, equipped with an adapter for band sawmills (marking BU 800P), is designed for saw blade sharpening. The saw band is guided along a massive mat fitted with permanent magnets to secure a firm fit to the wide band to the mat. By adjusting the height of the adapter, the position of the feed tip can be precisely adjusted. On all BU or BUH sharpeners, the standard is to adjust the rake angle, height and the pitch of the teeth, or simply replace the cam for the respective tooth shape. You will especially appreciate these BU and BUH sharpening properties when the sharpening band sawmills, where the toothing parameters need to be changed operatively according to the cutting conditions. For large band sawmills with a wide band, we supply sharpeners with a special linear feed mechanism and racks for guiding the long saw band. For sharpening of band sawmills with stellite or for very precise sharpening of common saws, it is possible to supply a sharpener with cooling (marked BUH 800P). The sharpener is equipped with infinitely variable feed control via a frequency inverter. Also, the speed of the sharpening wheel can be controlled by the frequency inverter. It is also possible to complete the sharpener with frame or saw blade sharpening adapters.

|

||||||||||||||||||||||||||||||||||||

BR 180 – semi-automatic sharpener for frame sawmillsSemi-automatic BR180 is a single-purpose machine for frame sawmills. Precise guiding of the saw tool and feeding on the feed bar ensures very precise sharpening of the tools and alignment of spacing even after incorrect previous sharpening. The sharpener is adjustable to the shape of the tooth, the angle of the forehead and the height of the teeth. The sharpening wheel sharps the entire tooth gap. The sharpener is particularly suitable for use directly in sawmill operations, where it ensures optimum sharpening of saw blades in high quality, while maintaining optimum toothing parameters, with very simple operation and without the need for qualified operators. The feed rate is infinitely adjustable by the frequency inverter.

|

||||||||||||||||||||||||||||||||||||

SHARPENING MACHINES

- To sharpen longitudinal saw blades (frame, band and circular saws) with steel blade, stellite or sintered carbide slices

- For both wet and dry grinding (with cooling)

- Semi-automatic sharpeners universal (series BU800, BUH800, BUHS800) and single-purpose (BR180), manual (BU2001)

STROJCAD RECOMMENDS

DOUBLE-BLADE CIRCULAR SAWMILL

CIRCULAR SWING-BLADE SAWMILL